Starch and Rice Noodle Production Lines

Starch Glass Vermicelli & Rice Noodle Factory Machine

We manufacture rice noodle production lines and starch cellophane glass noodle machines, which use rice as well as corn, potato and mung bean starch as raw materials to mass-produce instant rice noodles, starch vermicelli and rice vermicelli. Our noodle machinery series include double steamed rice noodle production line, friction self-heating cooked rice noodle production line, potato and bean flour production line, and fresh rice noodle production line.

Loading Image...

🡠 Scrollable 🡢

🡠 Scrollable 🡢

Heshan® Rice Noodle Production Line Showcase

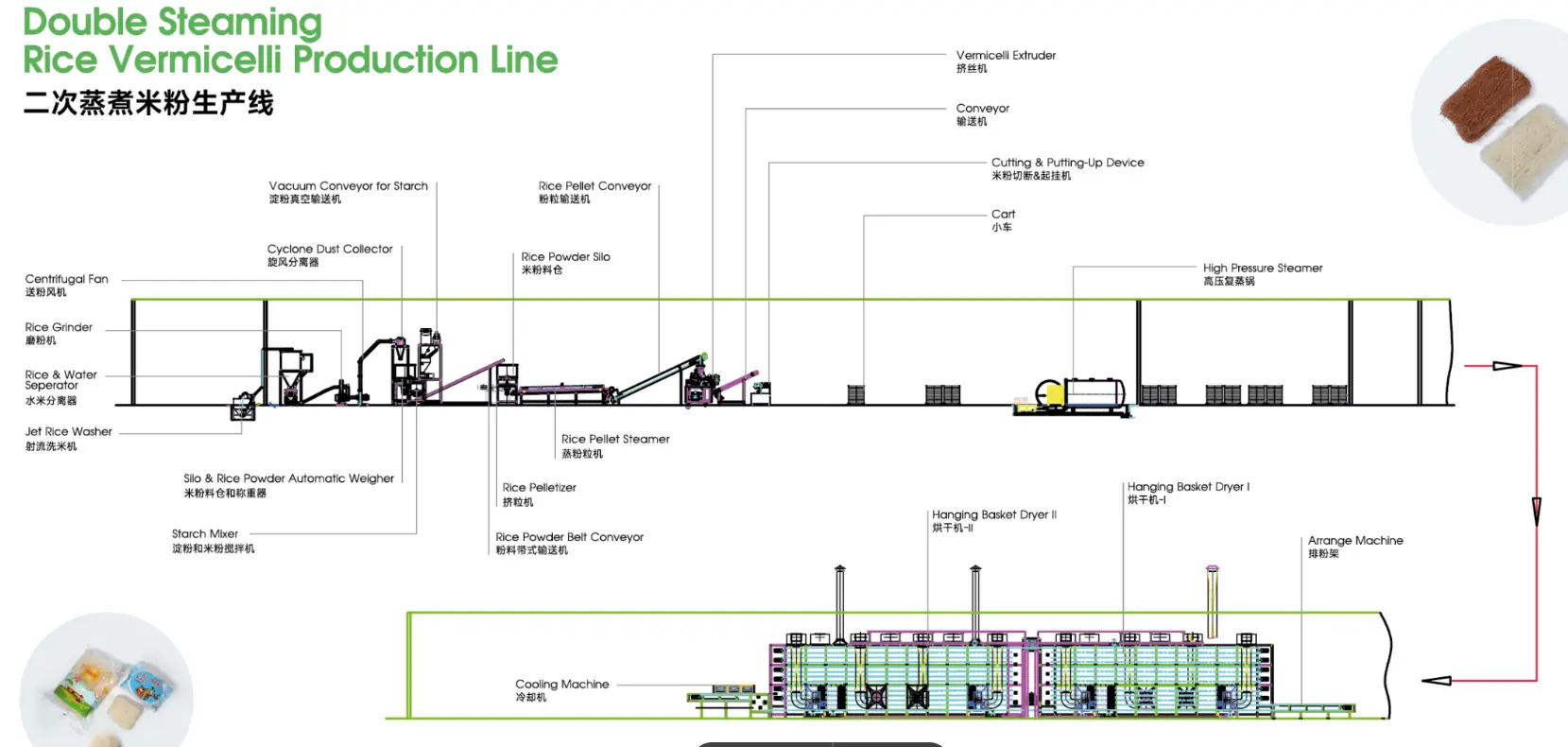

Bundled rice noodle production line - double-steaming pelleted feed stuff extrusion process

We are among the earliest of providers of the rice noodle production line and the rice stick noodle line. After the rice stick noodles are extruded they are steamed. Then the noodles are hanged on the hangers and dehydrated by hot air. The drying process is under comparatively lower temperature. The Heshan® Rice Stick Noodle Line produces Rice stick noodles through a series of process from semi-automatic to highly automatic. This flow sheet is a standard scheme which can be partially altered according to a specific requirement:

Rice Washing Machine → Water Absorption System → Rice & Water Separator → Rice Grinder → Starch Mixer → Pellet Extrusion → Rice Pellet Steamer → Rice Pellet Conveyor → Vermicelli Extruder → Length Cutting & Hanging-up → Pressure Steamer → Drying Machine → Cooling Machine

Corn/Bean/Potato Glass Vermicelli Noodle Production Line

When corn, bean, potato, rice starch, or other starch are used as the raw material the resulting products are transparent cellophane noodles. This is a highly automatic processing line featuring a robot mechanical arm to stock up the noodles before they are dried.

The instant rice vermicelli is so convenient that after only three minutes of cooking or steeping in hot water, it is ready for consumption with strong appetizing rice flavor. The automatic production of vermicelli through the following series of process:

Sand Removing → Milling → Rice Washing → Rice Soaking → Separating → Grinding → Pulp Filtering → Dehydrating → Steaming & Mixing → Rice Strip Extruding → Vermicelli Extruding → Cooling → Second Steaming → Cooling → Cutting → First Drying → SecondDrying → Cooling → Packing → Finished Products

Automatic Fresh Rice Noodle Making Machine

The Heshan® fresh rice noodle production line automatically produces fresh rice noodle strips or rolls through a series of process shown in the flowsheet bellow. The steaming machine is the central part the the assembly of the fresh rice noodle machines, which consists of the frame, steaming pot, starch distributing pan, pulp distributing mechanism, gear box, starch pump, steam piping and diesel burner. Its features are: short operation time for well cooked rice noodle and adjustable noodle trip thickness.

The fresh rice noodle is made by the following steps:

Rice Soaking-Mixing → Wet Rice Milling → Rice Slur Filtering → Rice Slur Concoction → Rice-Pasta-Sheet Steaming → Cooling → Soft Fresh Rice Noodle Rolling Machine → Wet Rice Noodle Cutting Machine → Fresh Rice Noodle Products

Automatic Fresh Lai Rice Noodle Production Line

Our automatic fresh rice noodle vermicelli machine, lai rice noodle production line makes lai rice noodles ("lai" means dripping line and this is how lai noodles are traditionally made) , also known as Laksa rice noodles, Asam rice noodles, Laksa rice noodles,Katong Laksa rice noodles, or Udon rice noodles. Firstly the rice is soaked in the soaking tanks; and then the rice is sent to the rice noodle machine miller to prepare a rice slurry; thirdly, the slurry is extruded from the self-heated lai rice noodle machine extruder to form round shaped lai rice noodles; finally the lai noodles are cooked in a steamer, quenched in cold water after steaming and the lai noodles are ready for packaging.

Instant Rice Noodle Production Line

Dry Ho Fan Rice Noodle Machine, Rice Vermicelli Machine,

This is the fine dried instant rice noodle machine that uses rice as raw material and produces snow-white and flexible instant rice vermicelli. The instant rice vermicelli is semi-transparent. We make vermicelli processing lines two types lines, namely the Rice Vermicelli Production Line by Rice Noodle Extruding Process and by rice noodle shredding process.